If there’s one thing universal about air compressors, it’s the ear-deafening sound. Working near a buzzing compressor for a long time can cause major physical issues like hearing damage. Now, instead of completely abandoning it, you can try to reduce the sound.

Try using a rubber isolation pad or muffler to reduce the noise level of an air compressor. You can also insulate the walls with acoustic foam or put a soundproof blanket on the motor for better results. If you’ve not bought one yet, opt for an electric model with dual pistons.

Here, we will provide the most effective solutions that will work for both industrial and indoor compressors.

So, if it sounds helpful, keep reading.

Why Do Air Compressors Make So Noise?

To understand why air compressors are so loud, you must learn how it works. The purpose of an air compressor is to store pressurized air inside a tank and use it in future tasks. It sucks in normal air and uses a piston to reduce the volume. It ultimately increases the pressure.

A piston, as the name sounds, is a moving metal part. It continuously moves up and down. That’s why you hear a whirring sound during the duty cycle.

Most air compressors produce 85 DB to 100 DB. Imagine a loud conversation you had with someone. That’s approximately 55 to 60 DB. As for an airplane taking off the ground, the sound goes up to 140 DB. That means 80 to 100 DB can be really painful to hear for a long time.

Apart from this universal cause, some other factors can increase the noise level of your air compressors. Have a look.

Reason 1: Loose Connection

A loose connection is pretty common if the air compressor is fairly old. We are talking about metal joints. If it’s true, you are in big trouble. Because loosely secured joints produce louder noise during a cycle.

Reason 2: Cheaper Quality

The quality and price of the air compressor also matter. Cheaper compressors don’t come with sufficient noise reduction features. It just simply does the work. No doubt, the noise level for these units can reach up to 100 DB. It’s deafening to the ears.

Reason 3: Large and Empty Room

The size and condition of the room also play a role. For example, the compressor produces a certain sound level in a small room. Now, keep the compressor in a large and empty warehouse. The place will further amplify the sound.

Related: Get the Size of Air Compressor with CFM/PSI to Paint Your Car Right Now!

3 Dangerous Air Compressor Sounds and What They Mean

Every air compressor makes a sound. It’s just how they work. There’s nothing to worry about. However, the noise gives cues about certain issues related to your compressor. Here’s how you can find that out.

1. Loud Banging Noise

A loud metal banging noise refers to serious issues with the piston. Most of the time, it occurs due to a loose pin.

2. Humming Sound

If your compressor is continuously humming, it can be an oil-related issue. You might need to check the oil level and refill the motor.

3. Bubbling Sound

A bubbling/hissing sound indicates the refrigerant or the cooling substance inside the unit might have leaked. That’s a hazardous situation. Inspect the compressor for any leakage thoroughly.

How To Quiet an Air Compressor?

Here comes the fun part. Even though you can’t expect the compressor to be completely silent, you can reduce the noise level. We have listed some effective methods below. Find the one most suitable for you and implement it.

#1. Rubber Isolation Pads

Installing rubber pads will be perfect if you are not a big fan of changing any parts. As you know, rubbers have great absorbing qualities.

Keeping the compressor on a bare floor is the most apparent reason why you hear such a loud gurgling sound. The motor vibrates at a high rate due to combustion. It causes friction with the floor and produces unbearable noise.

You can reduce the impact by placing some rubber isolation pads under the compressor. That way, the rubbers will absorb both the friction and noise.

#2. Soundproof Room

Try soundproofing the walls, if you never want to hear the air compressor again. Yes, most industries use this method to protect workers from hearing damage. All you need to do is keep every compressor in the same room. It’s better to build a separate compressor room.

Then, go for wooden walls instead of bricks. Finally, install some acoustic foam panels on the walls. That’s all. Now, the room won’t leak any sound from the buzzing compressor.

#3. Soundproof the Compressor

What will you do if the compressors are already installed in a big warehouse? Soundproofing the whole warehouse can take a heavy toll on your pocket. If you don’t have the resources to move them outside, there’s a way to soundproof the motor instead of the walls.

You can buy some wrapping mats for the motor. Check for elements like automotive butyl and foil. It can be a bit costly. But you get about 9 to 10 sheets within the package. That’s more than what you would need.

Just wrap the motor with this sheet, and you are ready.

#4. Keep a Distance

Keeping the compressor far from your house can be a great solution. Increasing the distance will surely reduce the impact. Most people build separate small housing in their backyard, garden, or garage. You can also put it in your basement to cut costs even more.

#5. Bury it Underground

Remember that distancing yourself from the compressor won’t quiet down the unit. You are only avoiding it at best. If you have more than one unit for commercial purposes, installing all of them outside would be a difficult task.

That’s when you need to bury the compressors underground seems best. It will reduce the noise level almost completely. Plus, you can install hose pipes to continue the airflow whenever you need it.

However, the temperature can affect the airflow inside the pipes. When it’s freezing, the air might get blocked and refuse to move at a decent rate.

You can cover the hose/pipe to protect it from extreme temperatures. This method is not something new. Professionals have been using this method for a long time.

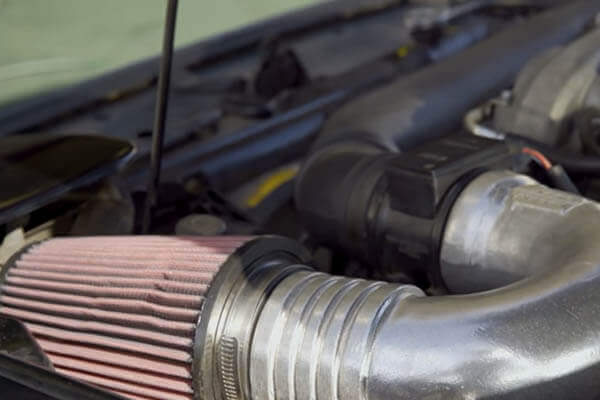

#6. Intake Muffler (DIY)

Using an air compressor muffler silencer is probably the cheapest way out there. But your DIY skills must be impressive for this method to work. Check out below.

- First of all, you will need two reinforced air hoses. Just look around the garage; you might easily find one.

- Take the hoses and connect one end to the compressor’s intake.

- The other end will go into an automotive muffler. Use your old/broken car’s muffler for this purpose. No need to buy one.

- Make sure the connection is tight and secured. You can attach foam pieces to the connection areas to reduce noise even more.

That was an easy-to-follow air compressor muffler DIY method. You can decrease the sound level by at least 4DB through this trick.

Note: Make sure that the automotive muffler doesn’t produce carbon. The motor intake can suck up carbon easily.

#7. Invest in a Commercial Muffler

If you have the resources, try buying an air compressor silencer kit (welded muffler) from the market. It’s super effective but expensive (around $200) at the same time.

The best thing about store-bought mufflers is the ease of installation. You need to connect the muffler to the compressor’s intake. Hence, the gurgling sound will enter the muffler only to be muffled by the sound-dampening elements.

As for our recommendation, whisper air compressor silencers provide good value.

#8. Regular Maintenance

Finally, you need to check the air compressor periodically for errors. Here are the two things you must consider during periodic inspections.

Lubricating

As discussed earlier, certain errors can increase the noise level. If you don’t want to experience that, try to lubricate the motor from time to time. Lubricating will reduce the impact of friction to a great extent. Oiling even helps the inner metal parts to last longer.

Cleaning Up the Filters

Wondering how to quiet an oil-less air compressor? Well, there you go. During the maintenance process, make sure to clean up the air filters. Air filters are quite susceptible to outer dust and debris. Those microparticles can keep building up on the filter window and affect the airflow. It leads to more issues, including overheating. So, try to get rid of as much debris as possible.

Is There Any Air Compressor with Lower Sound?

You can easily skip all the methods we mentioned earlier by opting for a low-sound option. Whenever we picture a compressor, a large moving piston comes into our minds. But that’s quite backdated to be true.

Nowadays, newer models like rotary screw compressors are becoming more popular. One major reason behind this popularity is how quiet these units are. Let’s look at some newer compressor models proven to be silent.

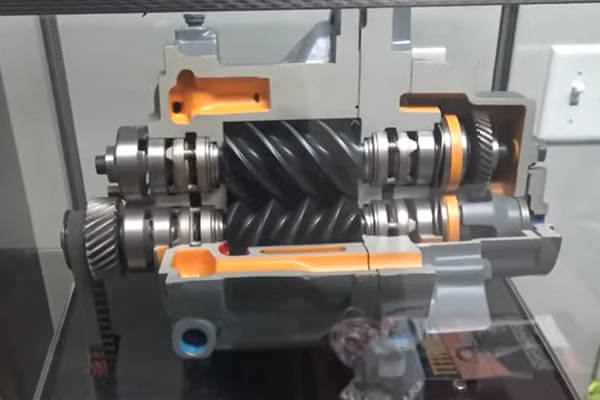

1. Rotary Screw

Instead of pressurizing all the air at once through a piston, such models come with a rotary screw. It traps the air between the rotor’s caves. This simple step helps to give you a quiet duty cycle.

Not to mention, rotary screw compressors are more expensive. That’s the reason why some users never consider them. But we think the price is worth it for the comfort it brings to your ears.

2. Dual Piston

You mightn’t know, but compressors come in single and dual-piston options. The single-piston models are famous for loud noises. Instead of that, try buying a dual-piston compressor. Fewer moving parts ensure that the sound level is quite bearable.

3. Electric Compressor

Thinking about getting a gas-powered compressor? We think it’s time to reconsider. You see, gas-powered compressors are noisy. But they are appropriate for outdoor usage. If you are thinking about how to quiet a pancake air compressor, switching to an electric one would be the best.

Electric ones work fine as an indoor compressor unit and produce power silently. However, you can choose this option if you are okay with low to medium-level power.

Final Note

Is your air compressor too loud? Then, difficulty in communication, lack of productivity, and sound pollution are some major consequences you might face daily. If you run a business, there’s even a risk of lawsuits due to sound pollution.

We suggest you go for a silent option while buying the compressor. Nowadays, most companies produce compressors with built-in mufflers. These options are significantly costlier. But the features are worth this much spending.

If you have already purchased one, follow the methods mentioned here to minimize the noise level. And that was our take on how to quiet a small air compressor. We hope the information was helpful.

Research Materials:

- https://www.quincycompressor.com/sound-reduction-air-compressors/

- https://www.wylerindustrial.com/air-compressors-industrial-sector/

- https://willingservice.com/compressor-making-loud-noise/

- https://www.quora.com/Why-are-air-compressors-so-loud

- https://www.youtube.com/watch?v=3m0FlyhMw0k

- https://www.youtube.com/watch?v=DnH7oqDBB6c

- https://www.wikihow.com/Soundproof-a-Wall-or-Ceiling#:~:text=Clean%20up%20any%20excess%20insulation,back%20of%20the%20drywall%20now