Air compressors work primarily by compressing air, which generates potential energy that can be stored in a tank for later use. As the compressed air is intentionally released, pressure develops and converts the potential energy into usable kinetic energy, much like an open balloon does.

The most prominent benefits of air compressors are their greater efficiency and the lack of bulky external motors compared to conventional equipment. It can be used for anything from inflating a tire to clearing out a clogged sink.

Moreover, you can check out the following article for more information on how does an air compressor work?

How Does an Air Compressor Work?

There are three primary phases to an air compressor’s operation: intake, compression, integrated storage, and discharge. The function of the air compressor is as follows.

1. Intake

The compressor pulls air from the outside environment with an intake valve or filter. It is necessary to filter the air to eliminate any contaminants that can cause harm to the compressor or the tools it drives.

2. Compression

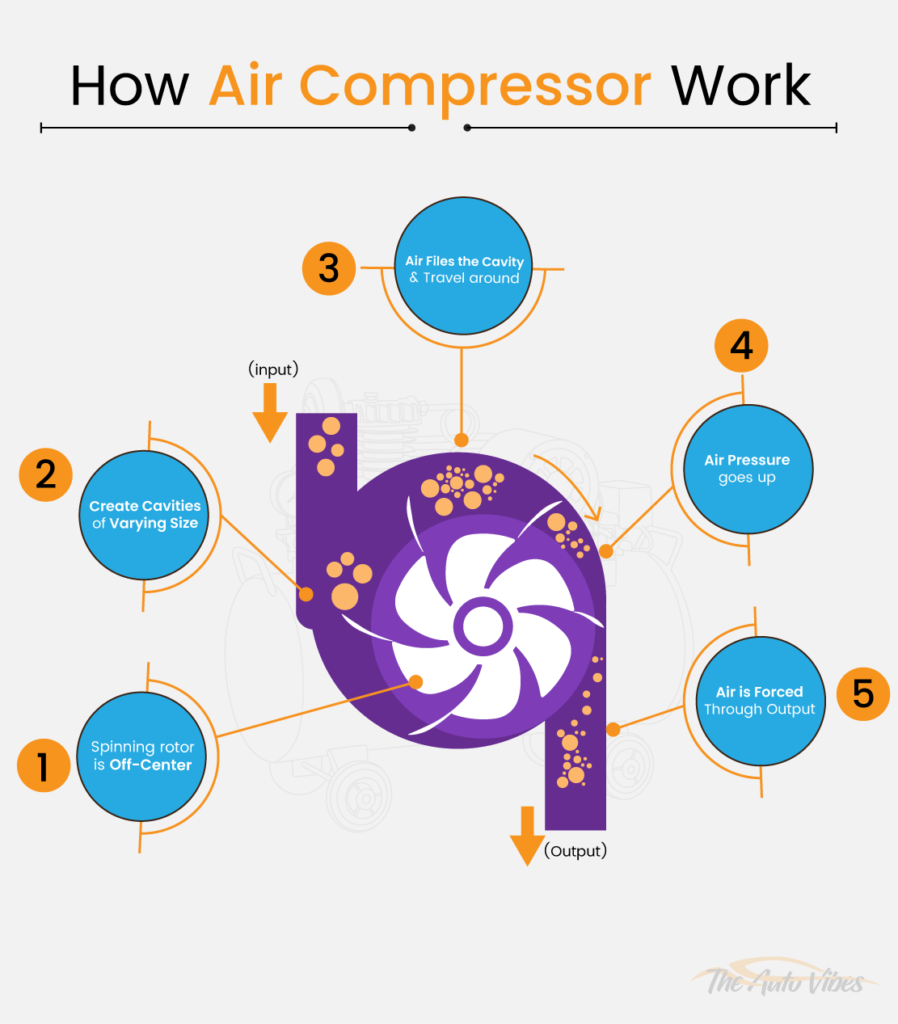

Once the air is drawn into the compressor, it is compressed by a piston, impeller, or another mechanism. Compressors may compress air by either positively or dynamically displacing it (also known as non-positive displacement).

- Compressors that use positive displacement to squeeze more air out of a given space.

- The air pressure is raised in dynamic displacement compressors, which first accelerate the air (raising its kinetic energy directly) and then slow it down.

No matter what kind of compression they do, all compressors are either lubricated with Oil or operate without it.

- Oil-lubricated compressors employ Oil in the compression chamber for various purposes, including lubrication, sealing, and cooling. Compressing air can cause a small quantity of Oil to be released into the air.

- In Oil-free compressors, no oil is released into the airflow. It doesn’t prove Oil isn’t utilized in the compression mechanism.

3. Integrated Storage

After being compressed, the air may flow into an inbuilt receiver tank. Several applications of integrated storage are dependent on the kind of compressor. But, the two factors are similar in several different varieties.

- Compressors with limited duty cycles, or those not intended to work constantly, employ internal storage to keep air accessible even when the machine is not in use.

- Modulating compressors, or compressors with controls that allow them to operate at less than full capacity, employ integrated storage to ensure that air is still accessible even when they are operating at a lower level.

4. Discharge

When compressed air is required, a discharge valve allows it to be released from the tank or reservoir and transferred through a hose or pipe to where it will be used. A pressure switch and a regulator control the air pressure and flow rate.

A power source is necessary for air compressors to function. Electric motors, gasoline or diesel engines, or other types of energy can all be used as the power source. Compressors often have their cooling systems to eliminate the excess heat generated by the compression process.

Depending on the intended use, the necessary pressure and flow rate, and other elements like energy efficiency and noise level, an air compressor of a certain kind and size is required.

How Does Each Type of Air Compressor Work?

There are many distinct air compressors, each with special uses and working theories, such as reciprocating compressors, rotary screw compressors, centrifugal compressors, and scroll compressors. The following explains the three primary compressor types and how they function.

1. Reciprocating/Piston Type

A piston (reciprocal) compressor employs pistons rotated by a crankshaft for high-pressure gas delivery. Instead, they are meant for something other than constant usage and are seen in smaller workplaces.

The compression of a reciprocating air compressor is accomplished by a piston that oscillates inside a cylinder. The intake valve opens when the piston moves down, allowing air to enter the cylinder. At the peak of the stroke, the discharge valve allows compressed air to be released.

2. Rotary Screw

Rotary screw air compressors are the go-to for experts due to their ability to provide the greater pressures required for sophisticated pneumatic and high-powered instruments.

A rotary screw compressor employs the rotation of two screws (rotors) to squeeze air. The air trapped between the screws is pressed when they come together. After being compressed, the air is released into a holding tank.

3. Centrifugal Compressors

A centrifugal compressor uses an impeller spinning at high speed to compress air by transforming the air’s kinetic energy into force. The air is released from the compressor and passed via a diffuser, where its velocity is reduced. Then its potential energy is transformed into pressure.

High-speed electric motors often power these compressors. In HVAC systems, centrifugal compressors are commonly utilized to circulate air and cool the interior.

FAQ

Several varieties of compressors are available. If put to such use, they would all pump water, but not efficiently. Indeed, air can be compressed, and one of the available types is the centrifugal compressor. But you can’t refer to it as a pump because it isn’t built to the same standards as a centrifugal water pump.

Electric air compressors typically require a voltage range of 110 to 120 volts to function. A 220V or 240V outlet is necessary for compressors with motors that produce more than two operating horsepower.

Only air compressors with a 100% duty cycle will do at the required pressure and flow rate. Overworking an air compressor causes it to wear down faster, necessitates more frequent repairs, and, in the worst case, causes an interruption in output.

It is common for there to be insufficient amounts of refrigerant in the system, which can lead to the compressor overheating, which is one of the primary causes of compressor failure.

According to Energy Star, the majority (76%) of an air compressor’s total lifespan cost is attributable to electricity. Compressed air is among the priciest commodities for many companies. An average industrial air compressor may rack up $800,000 in electrical bills during 10 of use.

Final Verdict

How does an air compressor work? I hope the previous article helped you understand this question better.

Generally, various compressed air applications call for varied air stream sizes. The three most important variables are air quality, movement, and pressure.

The basic air compression process is the same for all compressors, although some methods are unique to each class. The possible values for certain of the air stream’s dimensions can be constrained as a result of these discrepancies.

Therefore, using your compressed air will influence the compressor you need.