Automatic machining is becoming common now and this is all because of new and advanced features in the world of technology. Here we are going to introduce you to an automated manufacturing process which is indeed a human achievement. CNC processing! The process which has made human life comfy and hassle-free. This article explores CNC machining and explains it in simple terms. A cool process that lets you use computerized controls to operate machines. CNC machining relies on numerical control to make machines accurate and repeatable.

Key Components of CNC Machining

To understand how CNC machining is done, let’s just take a look at the kwy components only. There are different components of CNC machining like:

● Mills use moving cutting tools to remove the material from a workpiece.

● Lathes rotate the workpiece while cutting tools move to shape it.

● Routers, but, are ideal for cutting and shaping materials like wood and plastic.

Computer-Aided Design (CAD):

CAD is like a super-smart digital sketchpad for engineers and designers. Instead of using pencils and paper, they use special computer programs to form detailed 3D models of the things they want to make. It’s like drawing but with the added magic of computers.

Why CAD for CNC?

Now, let’s say you want to turn your digital creation into an actual physical object using a CNC machine. Here’s where the fun begins. CNC machines need clear instructions, like a GPS for cutting and shaping materials. CAD helps you create these instructions in a language the CNC machine understands.

How does CAD work for CNC?

As we have seen, what is CAD So basically how does CAD work for CNC? Here is a brief description of this.

● Drawing Your Idea:

You start by drawing your idea on the CAD software. It’s like building a digital version of your creation, from every angle imaginable.

● Adding Details

When you create something, you want to make sure every little thing is right. That’s where CAD comes in handy! This tool helps you add all the necessary info to your design. Like sizes, angles, curves, and anything else important. This makes sure everything turns out the way you want it to be.

● Choosing Materials

Once your digital design is ready, you pick the material you want to use. Wood, metal, plastic – you name it

● Creating Toolpaths

Now, let’s talk about the cool part! CAD software is like a magic wand that helps you make plans for the CNC machine. It gives the machine instructions on how to cut and shape your material to match the design you made on the computer.

● Precision Planning

CAD lets you plan everything with incredible precision. You decide where the CNC machine will cut, how deep it will go, and at what speed. It’s like giving super-detailed directions to a very skilled robot.

● Testing and Tweaking:

Before the real work starts with the CNC machine, you can pretend it is on the computer first. This way, you can find and fix any possible issues and make sure everything will be right.

● Ready for CNC:

Once you’re happy with your digital plan, you save it in a special file format that the CNC machine can read. It’s like giving the machine a set of instructions it can follow to bring your design to life.

Computer-Aided Manufacturing (CAM):

The most important component of CNC machining is CAM which is like a super-smart helper for your CNC machine. It’s the computer master that takes your cool drawing and turns it into step-by-step instructions for the machine to follow. It’s like giving the machine a recipe to make your spaceship the way you want it.

How exactly does CAM work for this automated machining? The operating standards of CAM for CNC machining are given below:

● Design the part:

You start with your amazing drawing, on a computer or even on paper.

● Meet CAM:

CAM is your friend who helps you turn the drawing into real stuff. It takes all the details from your drawing and makes a plan.

● Choosing Materials:

You pick the material for your spaceship. It could be wood, plastic, or anything you like!

● Creating the Plan:

CAM creates a special plan for the CNC machine. This plan tells the machine exactly where to cut, how deep to go, and how fast to do it. It’s like giving the machine a map to follow.

● Toolpaths – The Magic Trails:

CAM makes something called toolpaths. These are like magic. These magical tools show the machine where to move and how to shape the material to match your drawing.

● Testing the Plan:

Before the real work begins, CAM lets you test the plan on the computer. You can make sure everything looks good and fix anything that might need a little tweak.

● Ready for CNC Action:

Once the plan is perfect, you save it in a special language that the CNC machine understands. It’s like giving the machine a special set of instructions to bring your drawing to life!

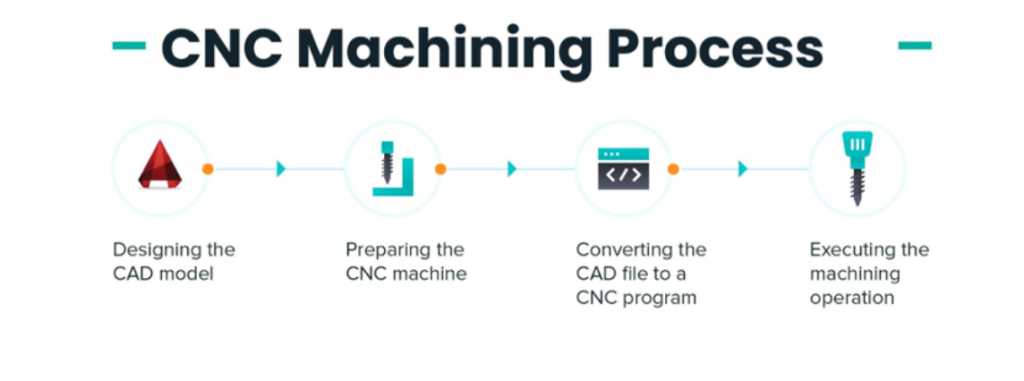

The CNC Machining Process:

The machining process of CNC consists of different steps as the model created by CNC machining is step-by-step oriented. The easy steps to create CNC machines are as follows:

1. Design the part:

Engineers like Super Creators use a computer program called CAD to draw detailed pictures of what they want to build. It’s like creating a digital model of a cool toy or special piece. This digital model becomes a treasure map-like plan that a CNC machine can follow.

2. Programming a CNC Machine:

Next, the CAD plan must be translated into a language that the CNC machine understands. CAM software assists in this conversion, creating a series of steps called G-codes. G-codes are like magical instructions that tell your CNC machine how to move, how fast, and how deep to cut. It’s like giving clear instructions to your robot friend.

3. Material Settings:

Before the CNC machine works, you must select the material you want to create. It can be wood, metal, or something else. Like preparing a canvas for painting, make sure that this material is provided to the machine’s working area.

4. Tool Setup:

as different jobs need different tools, CNC machines also need special cutting tools. Choose the right tools depending on the materials you use and how you want your work to look.

5. Operating a CNC Machine:

Now comes the exciting part. When the operator presses the start button, the CNC machine starts according to the plan. Cut, shape, and shape materials the way engineers design them in digital models. It’s like watching a robot transform a drawing into reality step by step.

Advantages of CNC Machining:

So why should you be using CNC machining? Here we will discuss some benefits to prove the worth of CNC machining.

1. Precision and Accuracy:

CNC machining is like having a super-precise robot friend. It cuts and shapes materials with accuracy, making sure every part is right. Imagine building a perfect puzzle – that’s how CNC brings precision to manufacturing.

2. Versatility:

CNC is a superhero in the workshop. It can work with all kinds of materials – wood, metal, plastic – you name it.

3. Creating Anything You Like:

CNC is like a superhero maker. It can make strong metal parts or cool wooden sculptures. Whether you need something tough or something artsy, CNC is good at it. It is like a helper in the market. It can make all types of things, making it very useful for making anything you imagine!

4. Efficiency:

CNC machines don’t waste time. Once you have a plan, you can do the same thing over and over again without getting bored. It’s like having many workers who do not need breaks, speeding up the making process and saving time.

5. Repeatability:

Making many of the same things? No problem for CNC! Once you have a plan, you can reuse it again and again. It never fails, ensuring consistent quality in every batch of production.

Applications of CNC Machining:

CNC machining is widely used in many applications. Some of the applications of CNC Machining are as follows:

1. Making Awesome Toys:

CNC machining is like a toy-making enhancer. It helps create super cool toys with precision, making sure every part fits. From toy cars to action figures, CNC makes playtime more fun!

2. Crafting Parts for Cars:

CNC is a car builder’s best friend. It shapes metal parts with amazing accuracy. It helps build strong and reliable cars.

3. Creating Neat Signs:

Ever seen those fancy signs? CNC makes them look extra fancy! It cuts and curves materials to create detailed signs for shops or special events. It’s like a sign-making superhero.

4. Building Space-age Stuff:

CNC is like a space explorer. It helps make parts for rockets and satellites with super precision. From tiny spaceship parts to big satellite parts, CNC plays a vital role in space adventures.

5. Designing Custom Furniture:

Want a unique chair or a special table? CNC is your furniture designer. It carves and shapes wood to create custom furniture pieces. It’s like having a woodworking friend who can make your dream furniture a reality.

6. Crafting Medical Devices:

CNC is a healthcare helper. It creates tiny, detailed parts for medical devices with precision. CNC ensures that everything fits and works for the care of a patient in surgery tools.

7. Building Clever Gadgets:

CNC is a gadget maker extraordinaire. It crafts intricate parts for electronic devices like smartphones and computers. It’s like the behind-the-scenes hero making sure our favorite gadgets work.

8. Constructing Airplane Components:

Ever wonder how airplanes stay up in the sky? CNC is part of the answer. It creates precise components for airplanes, ensuring they’re strong and reliable. It’s like the engineer’s tool for safe and smooth flights.

9. Making Unique Jewellery:

CNC is a jewelry artist. It carves and shapes metals to create beautiful and unique jewelry pieces. From delicate earrings to shiny necklaces, CNC adds a touch of precision to the world of fashion.

10. Building Playful Amusement Park Rides:

CNC is like an amusement park architect. It crafts parts for thrilling rides with precision. From roller coasters, CNC ensures that each ride is safe and exciting for everyone. It’s like bringing joy and excitement to the park!

Challenges and Solutions in CNC Machining:

The challenges are always present in every kind of system. But along with challenges, the solutions to these challenges are also present. Some of the challenges and their solutions in CNC machining are as follows:

1. Tool Wear: Keeping Tools Happy and Healthy

When we use tools a lot in CNC machining, they can get tired and worn out. It’s a bit like our favorite toys getting a bit worn from lots of play. To solve this, we need to check and fix the tools, making sure they stay in good shape. It’s like taking care of our tools so they can keep helping us make amazing things.

2. Complex Programming: Cracking the Code with Smart Software

Creating instructions for CNC machines can be a bit tricky, like solving a puzzle. But don’t worry! Smart computer programs, like CAM software, and skilled programmers are like superheroes. They make the difficult coding part easy and fast. it turns our ideas into real-life things without too much disturbance.

3. Material Limitations: Tackling Tough Materials with Tech Magic

Imagine you’re in a kitchen, and some foods are easier to chop than others. Well, in making things with machines (CNC machining), it’s the same – some materials are a bit tricky. But here’s the cool part. Smart researchers and tool experts are like wizards in a magical workshop. They’re working on better tools and smart plans to handle these tricky materials. It’s like they’re figuring out secret spells to make. CNC machines work better, so we can create all kinds of amazing things without any problems!

In conclusion, CNC machining is like having a superhero in your workshop. Very accurate and do things exactly the way we want them to. They transform our ideas into real and concrete things. CNC is not a tool. This is a creative partner that brings our imagination to life and helps make the world of things easier and cooler.