An Air compressor is a versatile and essential piece of equipment in every repair business. In addition to inflating tires and powering air tools, air compressors have many other uses.

However, greater compressors with higher voltage and the ability to create more cubic feet per minute offer excellent flexibility. For example, the motor of a 240-volt air compressor consumes more energy.

But it is more efficient than that of a 120-volt or other one. Therefore, when working with high voltage, you can be worried about the possible risks inherent.

So, in today’s article, we will specifically address the answer to the topic, of how to wire a 240v air compressor diagram?

Read the details below.

Effective Method to Wire a 240v Air Compressor Diagram

Before going into any details, read the manual to cover them before starting. Because of this, you will be able to comprehend the diagram and wire the compressor appropriately. Now moving on to the details of the wiring diagram for a 240V air compressor, let’s get started.

Tools You Need:

Screwdriver, wire strippers, wire cutters, and 240v air compressor.

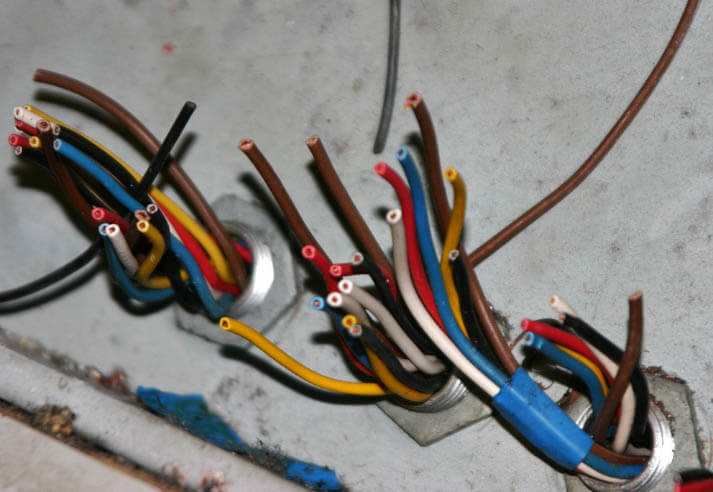

1. Cut the wires

If you want to hook your air compressors to an electrical outlet, you’ll need to cut some wires first. Make sure there is enough gap in the cords so that everything can be plugged in without any hassle.

2. Take wire stripper

Use a wire stripper to remove the protective covering from the ends of each wire. Work cautiously at this point since careless staff can cause wire damage.

3. Loosen the screw

Use a screwdriver to release the screws after the wires have been stripped. You need to start by removing the screw holding the air compressor’s cover plate. Remove the protective cover and store it safely until its next use.

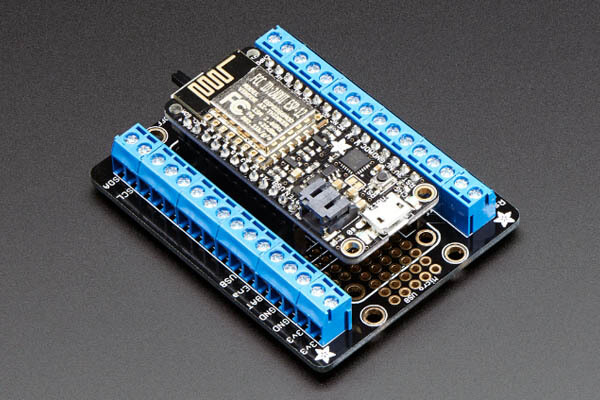

4. Insert terminal block

Identify the terminal block within the air compressor and determine which terminals are the power input and which are the power output. The “L1” and “L2” will be placed at the power input and output, respectively.

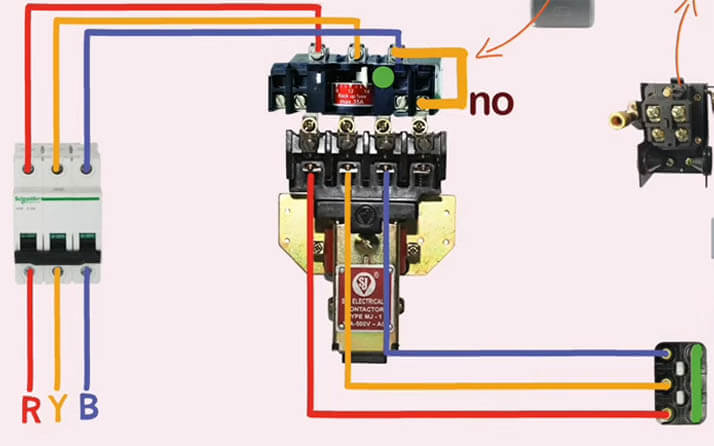

5. Connect the wire

At this point in the process, you need to connect the wire from the power supply to the air compressor’s “L1” terminal before connecting it to the air compressor itself. Check to make sure the connection is stable and secure.

Finally, connect the wire from the air compressor to the “L2” connection here at the power source. Perform one more security check on the connection to verify that it is secure. Now is the time to replace the air compressor’s cover plate and secure it with the provided screws.

Once you’ve finished hooking it up, you will need to activate the power supply to confirm that the air compressor is functioning appropriately.

Some Useful Tips for Wiring a 240-Air Compressor Diagram

The following suggestions will help you do your job more effectively and will make it simpler when wiring a 240-air compressor diagram.

- Ensure all the connectors are secure and strong well before switching on the power to prevent any unintentional problems.

- The most crucial thing to keep in mind when working is to ensure you have the proper type and size of wire. Never use wires that are broken or that are ragged.

- Make sure no grit or dirt is stuck in any of the connectors.

- Do not attempt to repair or replace any wiring component until the power has been turned off. The power must turn off before any work is done in the wiring.

- Check the wire regularly for any necessary repairs since if it fails, you or anybody else working with it runs the risk of getting hurt or having an accident.

What Gauge of Wire Should Be Used with a 240-Volt Air Compressor?

An extra-large wire is needed for the typical 240-air compressor. Sizes 4 AWG and 6 AWG are suggested for use up to 60 amps, while 8 AWG is suitable for up to 30 amps. Don’t use a too big wire since this might increase the current and cause your air compressor to be overheated and break.

Related: Get the Size of Air Compressor with CFM/PSI to Paint Your Car Right Now!

However, you should check its amperage rating if you still have trouble determining the optimal size for your 25o volt air compressor. The air compressor’s amperage rating is often displayed on the device’s nameplate. The amperage rating of your air compressor will tell you what size wire you need to connect it to an outlet.

FAQ

The recommended circuit breaker amperage for a 3.7 hp and 240 V air compressor is 20 amps. Because a 3.7 horsepower, the 240-volt air compressor will require more than 18 amps when it is first turned on, a circuit breaker rated for only 15 amps won’t be capable of handling the electrical load.

A 30-amp circuit breaker is required for a 60-gallon, 5-horsepower, 220-volt air compressor. To guarantee that the machine won’t have electrical problems while in operation, utilize a 10/3 wire as well as make sure the hot wires are connected to the appropriate terminals.

A typical 240V outlet seen in homes has either three or four prongs: two for the “hot” wires carrying 120V, one for the “neutral” or “ground” wire, and one for the “ground.” Refer to Figure 3 for further clarification. Regarding gadgets that use 120 Volts, such as a fan or clock, the neutral wire enables the equipment to function using only one of the hot wires.

Yes, a 240-volt air compressor requires a neutral. This is because maintaining a steady flow of energy is essential to the compressor’s proper functioning.

Without a neutral, voltage spikes may short out the compressor or reduce its efficiency. Therefore, a 240-volt air compressor cannot operate correctly or without a neutral.

Nearly all modern air compressors are run on electricity. To allow the air compressor to fill up, you can plug it in. A three-prong plug may be necessary for larger compressors, while a two-prong plug is typical for smaller units. Make that the compressor can plug into outlets that can handle its voltage.

Final Verdict

So, now you know how to wire a 240v air compressor diagram. Hopefully, you shouldn’t run into any problems if you were a 240-volt air compressor according to the above instructions.

However, following all necessary safety measures for working with electricity is critical. In any situation you are doubtful about something, you should never hesitate to seek the guidance of an expert electrician.