Let it be a garage, factory, or industrial shop, air compressors are known to be vital equipment. Because from filling gas cylinders to providing heavy-pressure air, it can do it all! But despite having the ability to refill itself, it’s prone to run out of air from time to time.

So, why do air compressors run out of air? There can be a leakage issue with the air tank or hoses that you probably haven’t noticed yet. Or let’s say the tube fitting isn’t tight enough, which causes the air to escape.

Wave off your worries as we’ve shared a detailed discussion on how air runs out of the compressor, including the best way of preventing it.

Can An Air Compressor Refill Itself?

Air compressors are liable to collect atmospheric air and keep it stored in a particular tank. And surprisingly, most of them come with a self-refilling ability! This means the motor of the compressor will start cycling off and on to fill up the required pressurized air.

With that being said, a few things can cause an air compressor to run out unexpectedly. In that case, the air mightn’t be able to refill back into the tank, despite having a self-refilling ability!

What Causes Air Compressors to Run Out of Air?

As we’ve said before, so many reasons are responsible for running air out of your self-refillable air compressor. As a result of that, you may find it necessary to refill the air by yourself. But before doing this, let’s first detect the prime causes:

Air Leakage

Air leakage around the air compressor is a common issue behind unexpected run-out. It’s often noticeable around the hoses and tank, and low air pressure is one of the core signs of air leakage.

From the oil-filling tube to underneath the hood, inspecting all the nooks and crannies is what you must do to find the leak spot. Sealing would be the prime solution to eliminate air run-out issues with the air compressor.

Loose Tube Fitting

Novice users often make mistakes during the air compressor attachment by keeping the tube fittings loose. And that’s when the air starts running out without leaving any significant signs. To prevent it, you must tighten the tube fittings as much as needed.

Faulty or Leaky Valves

A damaged check valve is just enough to pass air through the compressor, causing unintentional run-out. Similarly, if there is any leakage on the safety valve, it will equally become unable to hold the air.

So here, there is nothing to do except for replacing those stuff to get rid of the air run-out issue.

How to Prevent Air Compressor Leakage That Causes Air Running Out?

There is a common saying, “prevention is better than cure!” Here, I’d like to share some handy tips you can follow to avoid air compressor leaking. In this way, you won’t have to spend bundles of bucks on the replacement. So, these are as follows:

Inspecting & Tightening the Connection

Pay attention to the connection between the air compressor and hose, making sure everything is tight enough, and no air is running out. Consult an expert if you find any loose connection right there.

Going for Small Repairing

Over time, tiny rubber components like valve seals or O-rings get cracked. The same thing goes for the air filter, tube, and hose. If you overlook the necessity of replacing them within the required time, a bigger issue may take place in! So, don’t think twice about replacing those tiny parts.

Step-by-Step Process on How to Refill Air Tank

So, if your air compressor is running out of air excessively, it’s necessary to fix them and then refill the tank by yourself. After consulting an expert in terms of repairing, move on to refill it!

And for your convenience, we’ve shared a couple of steps to perform the task safely and effortlessly:

Step 1: Collect Safety Gear

While dealing with the air tank refilling task, there is no need to cover yourself up with every single safety dress. However, it is safe to keep your eyes well-protected by putting on safety goggles.

Step 2: Tank Observation

Here is where you need to inspect the tank from head to toe, starting from the exterior dents. Note that an old air compression tank may contain pesky little pin-holes and rust!

Besides, the hose might appear with tiny holes and leakage, which first needs to be replaced before you refill the tank.

Now, around the fill valve, start rotating the plastic ring anticlockwise, enabling the air to pass through or out of the compression tank.

Step-3: Refilling the Air

Before starting the air compressor, let’s get prepared to fill your air tank. Here, slightly pushes the hose in opposition to the valve in terms of achieving the desired fill. During that period, you may notice a “hissing sound” till lining up everything.

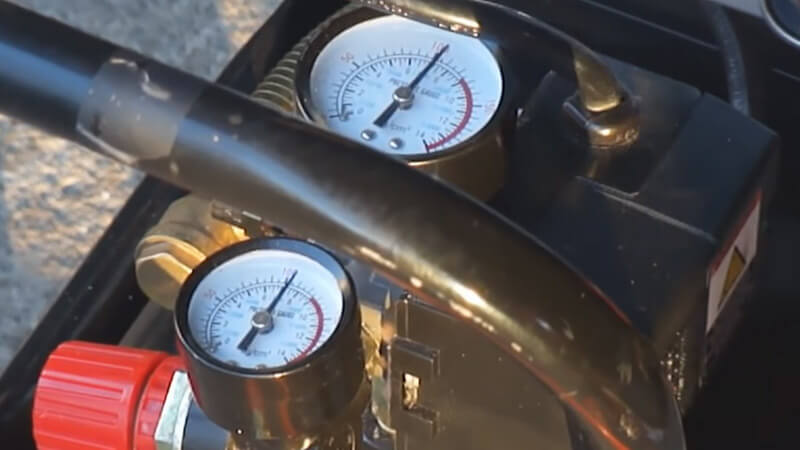

At that time, keep your eyes on the pressure gauge on your air compressor. Once you notice the PSI has arrived at the recommended mark (e.g. 85-125), stop refilling immediately. To avoid overfilling, experts suggest not touching the gauge’s red zone.

After completing the task, simply take the airline off and shut down the fill valve so that air can’t escape at all.

What If an Air Compressor Runs Continuously?

Having pin-holes around the fittings, inappropriate piping connections, and electrical failure are some of the key reasons behind frequent air running. When it happens, the system must be examined by an expert to detect potential leaks and holes, which you aren’t able to seal.

Sometimes, mechanical issues can also be a reason behind running the air compressor continuously. In fact, its repair might be pricier, especially if you fail to detect it before anything affects it significantly.

FAQ

Do you have more queries to learn about air compressors running out of air? From the air compressor’s life expectancy to experts’ recommendations, I shared several crucial things through the question-answers.

So, keep on reading:

Leakage issues have always been one of the prime reasons why air compressors run out. Depending on the spot of leakage, you need to tighten the joints, repair pinholes, and replace valve seals to get rid of the bummer.

In simple terms, trapped air is unable to pass through the air due to the obstructed vents. Over time, it results in serious overheating issues with the air compressor, and that’s when accidental burnout occurs from time to time.

There might be something wrong around the piston seals that causes leakage on the oil fill tube. In most cases, a worn-out piston seal leaks air, which needs to be replaced as soon as possible to eliminate future inconveniences.

Depending on the type of air compressor, the lifespan will vary. Let’s say a typical reciprocating air compressor will last around 5-15 years. The life expectancy also depends on how you treat it, the way of maintenance, and so on.

Final Words

Based on my research and personal experience, we’ve come up with a verdict that leakage is the main culprit behind frequent air run out, which needs to be eliminated through repairing or replacing.

But sometimes, even after there is not a single leak in the air compressor, you still might notice the air is running out. At that time, pay attention to the spot where the hose and compressor are connected. Fasteners or hoses mightn’t be attached tightly, which is why it’s failing to hold the air inside.

Lastly, if you fail to locate leaks, consider hiring a professional to take the necessary help from him.